Innovations in Concrete Mix Designs for Sustainable Construction in 2025

- SAICEL

- Sep 4, 2025

- 35 min read

Updated: Sep 4, 2025

Concrete mix design is critical in construction, affecting the performance and sustainability of structures. As we approach 2025, the concrete industry is on the brink of transformative advancements. This blog post will explore the innovations in concrete mix designs, focusing on sustainability, performance, and real-world applications.

The Importance of Concrete Mix Design

Concrete mix design involves determining the proportions of materials such as cement, water, aggregates, and admixtures to create concrete with desired properties. The quality and characteristics of the mix design significantly affect concrete performance. To create an effective concrete mix, consider the following criteria:

1. Appropriate strength: The mix should achieve the required strength for the structure, typically specified by engineers.

2. Consistent workability: The mix should have the necessary workability or consistency to match the construction method. For instance, a stiff mix is needed for vertical structures, while a flowable mix suits concrete pumping.

3. Durability: The mix must withstand environmental factors like freeze-thaw cycles, corrosion, and abrasion.

4. Good finishing properties: The mix should result in a smooth, level, and visually appealing surface.

5. Cost-effectiveness: A well-designed mix should minimize the costs of materials, equipment, and labor.

6. Sustainability: The mix should aim to reduce environmental impact by using recycled materials or lowering CO2 emissions.

By adhering to these criteria, a concrete mix design can produce high-quality concrete that meets structural performance requirements while minimizing costs and environmental impact.

Carbon-Free Concrete Mix Design

The demand for carbon-free concrete has surged as environmental issues gain urgency. New materials, such as recycled aggregates and alternative binders like fly ash, are leading the way to sustainable concrete solutions. For instance, using recycled aggregates can reduce the environmental impact of concrete production by up to 30%.

In addition, carbon capture technologies are being integrated into the mixing process, enabling significant reductions in CO2 emissions. By 2025, we can expect widespread adoption of these methods, fostering eco-friendly concrete mixes without sacrificing performance.

Concrete Mix Properties

Engineers and construction professionals must understand the properties of concrete mixes. The key properties include:

Strength: Determines how much load concrete can bear without failure.

Durability: Indicates how well the concrete can resist weather, chemical attacks, and wear.

Workability: Refers to how easily the concrete can be mixed, placed, and finished.

A well-structured concrete mix carefully balances these factors to satisfy project requirements and conditions.

Applications of Concrete in Construction Projects

Concrete is used in numerous construction applications, ranging from homes to large infrastructure projects. Some notable applications include:

Shotcrete: This method sprays concrete at high velocity, ideal for tunnels and slope stabilization, especially where conventional concrete placement is difficult.

Precast Concrete: Concrete elements are cast in a controlled shop setting before being moved to the construction site. This method enhances quality and efficiency, particularly in modular construction, reducing on-site waste by up to 40%.

Super Strength Concrete: Built for extreme loads, this type is used in high-rise buildings and bridges. Its specialized design significantly enhances structural integrity under demanding conditions.

Underwater Concrete: Designed to set and cure while submerged, this concrete is crucial for marine projects like piers and foundations, ensuring structural safety even in challenging conditions.

Types of Concrete Mix Designs

Many concrete mix designs cater to specific project needs. Here are some common types:

Nominal Mixes: Fixed proportions of ingredients, suited for general construction purposes.

Design Mixes: Engineered to meet specific performance criteria such as strength and durability, often critical for high-stake applications.

High-Performance Concrete: Delivers superior strength, durability, and workability in demanding environments, making it a top choice for modern engineering projects.

As we approach 2025, the trend toward sustainable and high-performance concrete mixes will increase, fueled by advancements in technology and materials.

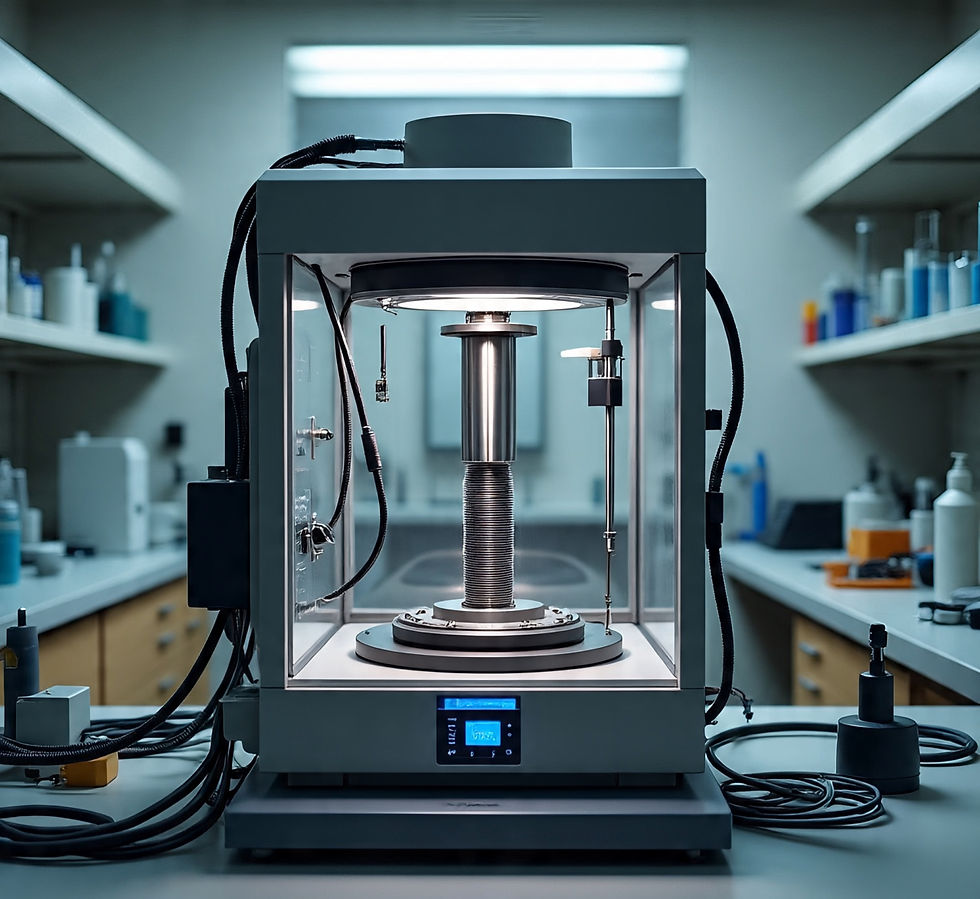

The Role of Mixers and Testing Technologies

The future of concrete mix designs is greatly influenced by innovations in mixers and testing technologies. Modern mixing equipment is being designed to ensure a consistent and uniform mix. These advanced mixers can work with various materials, including recycled aggregates, facilitating the creation of sustainable mixtures.

Moreover, real-time monitoring systems are being introduced for testing properties during the mixing and curing process. These technologies allow engineers to make informed decisions, ensuring that the final product meets strict quality specifications.

Concrete Testing Techniques

Concrete testing is crucial throughout all construction stages, from planning and placement to long-term maintenance. Here is an in-depth look at advanced and emerging testing techniques used globally in 2025.

Destructive Testing Techniques

These techniques involve physically altering or damaging the concrete to evaluate its properties.

1. Concrete Coring: Concrete coring is a specialized process that involves the extraction of cylindrical samples from concrete structures using advanced diamond-tipped drills. These drills are designed to cut through the dense and tough material of concrete with precision, ensuring that the integrity of the sample is maintained during the extraction process. The core samples typically have a diameter that can range from 1 to 6 inches, depending on the specific requirements of the testing and analysis being conducted. Once the cylindrical samples are successfully extracted, they undergo a series of rigorous tests to evaluate various properties of the concrete.

One of the primary tests performed is the assessment of compressive strength, which measures the material's ability to withstand axial loads without failure. This is crucial for determining whether the concrete meets the necessary structural requirements and standards for safety and durability.

In addition to compressive strength testing, the density of the concrete is also measured. Density is an important parameter that can provide insights into the material's composition and the presence of any voids or imperfections within the concrete matrix. A higher density often indicates a higher quality concrete mix, while lower density may suggest issues such as improper mixing or the inclusion of unwanted materials.

Furthermore, the composition of the concrete is analyzed to identify the types and proportions of materials used in the mix, including aggregates, cement, water, and any additives. This compositional analysis is essential for forensic investigations, particularly in cases where the performance of the concrete is in question, such as structural failures or deterioration over time. Understanding the composition helps engineers and researchers determine the cause of any issues and aids in developing strategies for remediation or improvement. Concrete coring is commonly employed in various fields, including forensic analysis and quality assurance. In forensic engineering, it plays a vital role in investigating structural failures, allowing experts to collect evidence directly from the site of a failure. By analyzing the core samples, they can ascertain whether the concrete met design specifications and standards at the time of construction, which is critical in legal cases and insurance claims. In quality assurance, concrete coring is used to ensure that the concrete used in construction projects adheres to industry standards and specifications.

Regular coring and testing can help identify potential problems early in the construction process, enabling corrective measures to be taken before the concrete is put into service. This proactive approach not only enhances the safety and longevity of the structure but also contributes to the overall efficiency and effectiveness of construction practices. In summary, concrete coring is a vital technique in both forensic analysis and quality assurance, providing valuable insights into the properties and performance of concrete. Through the use of sophisticated diamond-tipped drills, engineers and researchers can extract samples that are then meticulously tested for compressive strength, density, and composition, ensuring that the concrete meets the necessary standards for structural integrity and safety.

2. Pull-Out Test: The Pull-Out Test is a widely recognized and extensively utilized method in the field of civil engineering and construction, specifically designed to measure the force required to extract a metal insert, such as a rebar or anchor, that has been embedded in concrete. This testing procedure plays a crucial role in assessing the structural integrity and performance of concrete elements in various construction applications.

Purpose and Importance of the Pull-Out Test This test is particularly valuable as it provides critical data regarding the in-place strength of the concrete as well as the bond characteristics between the metal insert and the surrounding concrete matrix. Understanding these parameters is essential for engineers and construction professionals, as they directly impact the durability and safety of the structures being built. The Pull-Out Test helps in determining whether the embedded metal insert can withstand the expected loads and forces once the structure is put into service.

Testing Procedure The Pull-Out Test typically involves the following steps:

1Preparation of the Test Specimen: A concrete specimen is prepared, which may be a part of a larger structure or a separate test block. The metal insert is embedded into the concrete at a specified depth and orientation.

Curing the Concrete: After the insert is placed, the concrete must be allowed to cure adequately. This curing process is crucial as it influences the bond strength between the metal and the concrete.

Setting Up the Pull-Out Apparatus: Once the concrete has cured, a pulling device is attached to the metal insert. This device is calibrated to apply a controlled force vertically.

Conducting the Test: The pulling force is gradually increased until the metal insert is pulled out of the concrete. The maximum force exerted at the point of failure is recorded. This force is indicative of the bond strength and the in-place concrete quality.

Applications of the Pull-Out Test The Pull-Out Test is widely applicable in various scenarios, including: -

Quality Control: It serves as a quality control measure during construction, ensuring that the concrete mix and placement techniques meet specified standards.

Structural Assessment: In existing structures, the Pull-Out Test can be used to assess the condition of concrete and the effectiveness of the bond between embedded reinforcements and the concrete, especially in rehabilitation projects.

Research and Development: Engineers and researchers utilize this test to study new materials, bonding agents, and construction techniques, allowing for advancements in concrete technology.

Advantages of the Pull-Out Test One of the primary advantages of the Pull-Out Test is its simplicity and efficiency. It can be performed relatively quickly and does not require extensive laboratory equipment. Moreover, the test can provide immediate feedback on the bond strength, allowing for timely adjustments in construction practices if necessary. The results can also help in predicting the long-term performance of the embedded inserts under various load conditions.

Conclusion In summary, the Pull-Out Test is an essential tool in civil engineering and construction, providing valuable insights into the bond strength between metal inserts and concrete. Its ability to deliver critical data regarding the in-place strength of concrete makes it indispensable for ensuring the safety and durability of structures. By utilizing this test, engineers can make informed decisions that enhance the quality and reliability of construction projects, ultimately contributing to the overall success of the built environment.

Purpose and Importance The primary purpose of conducting a Pull-Out Test is to assess the performance and reliability of the embedded metal components under various loading conditions. Understanding the bond strength is crucial for ensuring that the structural integrity of concrete elements is maintained, especially in applications where the metal insert plays a pivotal role in load transfer or stabilization. For instance, in construction projects involving high-stress environments, such as bridges or high-rise buildings, knowing the pull-out strength can help engineers design safer and more effective structures.

Methodology The Pull-Out Test involves several steps to ensure accurate and reliable results. Initially, the metal insert is placed into a pre-drilled hole in the concrete and is often set with an appropriate adhesive or grout to enhance bonding. Once the material has cured, a specialized testing apparatus is used to apply a tensile force to the metal insert. This apparatus typically consists of a hydraulic or mechanical system capable of generating controlled and measurable forces. As the force is gradually increased, the test measures the amount of pull needed to extract the insert from the concrete.

The maximum force recorded at the point of failure provides a direct indication of the bond strength between the metal and the concrete. Additionally, the test can be conducted at various intervals after the concrete has cured, allowing for an analysis of how the bond strength develops over time.

Applications The results obtained from a Pull-Out Test are invaluable across various applications. For instance, in quality control processes during construction, the test can be used to verify that the concrete mix design and placement techniques have resulted in adequate bonding properties.

Furthermore, in repair and retrofitting projects, the pull-out strength can help determine the effectiveness of existing bonds and whether additional reinforcement is necessary. Limitations While the Pull-Out Test provides significant insights into bond strength, it is essential to acknowledge its limitations. The test results can be influenced by various factors, including the quality of the concrete, the type of metal insert used, the method of installation, and environmental conditions.

Therefore, it is crucial to interpret the results in conjunction with other testing methods and engineering assessments to obtain a comprehensive understanding of the structural performance. In conclusion, the Pull-Out Test is a fundamental procedure that plays a vital role in evaluating the bond strength and overall performance of metal inserts within concrete structures. By measuring the force required to extract these inserts, engineers and construction professionals can make informed decisions that enhance safety and durability in their projects.

3. Exploratory Openings: Exploratory openings are strategically created controlled breaks in concrete structures, designed to allow for thorough inspection and assessment of the internal conditions of the concrete. These openings serve a crucial role in the maintenance and evaluation of concrete integrity, as they provide direct access to the underlying materials and support systems that are not visible from the surface.

The primary purpose of these exploratory openings is to verify the placement of reinforcement within the concrete. This is essential because improper placement can lead to reduced structural performance and increased risk of failure. Inspectors utilize these openings to confirm that steel reinforcement bars, or rebar, are positioned correctly according to engineering specifications. This verification process is vital for ensuring that the concrete can withstand the intended loads and stresses over its lifespan.

In addition to verifying reinforcement placement, exploratory openings are also utilized to assess the condition of the concrete itself. Over time, various factors such as environmental exposure, chemical attack, and physical wear can lead to deterioration of the concrete material. By inspecting the internal surfaces through these openings, engineers can identify signs of distress, such as cracking, spalling, or delamination, which may indicate a need for repair or reinforcement. Moreover, these openings are instrumental in detecting defects that may not be apparent from the exterior.

Common defects include honeycombing, which occurs when the concrete mix does not fill all voids, and voids or air pockets that can compromise structural integrity. By examining the interior surfaces, inspectors can determine the extent of any defects and recommend appropriate remedial actions to enhance the longevity and safety of the structure.

The process of creating exploratory openings must be carried out with precision and care to minimize damage to the surrounding concrete and to ensure the safety of personnel involved in the inspection. Typically, specialized tools and techniques are employed to create these openings, allowing for a controlled and systematic approach to investigation. In summary, exploratory openings are a vital component of concrete inspection and maintenance strategies.

They enable engineers and inspectors to gain valuable insights into the internal conditions of concrete structures, ensuring that reinforcement is correctly placed, assessing deterioration, and identifying defects. This proactive approach helps to maintain the structural integrity and safety of concrete constructions, ultimately extending their service life and performance.

4. Beam Flexural Testing: Beam flexural testing is a crucial experimental procedure employed in the field of civil engineering and materials science to evaluate the flexural strength of concrete beams. This testing method involves subjecting concrete beams to a controlled loading process until they reach failure, which allows for the precise measurement of their flexural strength characteristics.

The process begins with the preparation of concrete beams, which are typically cast in standardized dimensions to ensure consistency and reliability in results. These beams are allowed to cure for a specified period, ensuring that the concrete achieves its intended strength before testing. Once cured, the beams are placed in a testing apparatus, often a universal testing machine, which applies a load at specific points along the beam’s length.

As the load increases, careful observation and measurement are conducted to monitor the behavior of the beam. The application of load continues until the beam fails, which may manifest as cracking, yielding, or complete structural failure. Throughout this process, data is collected regarding the load applied and the corresponding deflection of the beam, which is critical for calculating the flexural strength.

The results obtained from beam flexural testing are vital for several reasons. First and foremost, they provide essential data for the design and validation of pavements and slabs, ensuring that these structures can withstand the anticipated loads during their service life. The flexural strength of concrete is a key parameter that influences the overall performance and durability of concrete structures, particularly in applications where bending stresses are prevalent. Moreover, the findings from flexural testing can help engineers and designers make informed decisions regarding material selection and mix design.

By understanding the flexural properties of different concrete formulations, it is possible to optimize the performance of concrete in various environmental conditions and loading scenarios. In addition to its application in pavement and slab design, beam flexural testing is also instrumental in research and development within the field of concrete technology. It aids in the exploration of new additives, reinforcement materials, and innovative construction techniques, contributing to advancements in the overall quality and performance of concrete structures.

In summary, beam flexural testing is a fundamental procedure that not only assesses the flexural strength of concrete beams but also plays a critical role in the design, validation, and advancement of concrete applications in civil engineering. Its significance extends beyond mere measurement, influencing best practices in construction and paving the way for more resilient and durable infrastructure.

5. Split Cylinder Test is a critical method used in materials science and engineering to evaluate the tensile strength of various materials, particularly concrete and other composite materials. This test involves applying a diametral compressive load to a cylindrical specimen, which is typically shaped to have a specific diameter and height. The primary aim of the test is to induce tensile stress within the material, which can lead to cracking or failure. By measuring the load at which the material fails, engineers can determine its tensile strength, an essential property that influences how materials perform under stress.

The procedure for conducting the Split Cylinder Test is quite straightforward yet requires careful execution to ensure accurate results. Initially, the cylindrical specimen is prepared according to standard dimensions, often following guidelines set by organizations such as ASTM (American Society for Testing and Materials) or similar bodies. Once the specimen is ready, it is placed horizontally between two platens of a testing machine. A compressive load is then applied diametrically across the cylinder until the specimen fractures. The load at which the fracture occurs is recorded, and this data is used to calculate the tensile strength of the material based on the geometry of the cylinder and the applied load.

This test is particularly valuable for assessing the cracking resistance of materials. Cracking can significantly affect the durability and structural integrity of concrete structures, making it imperative to understand how different mixtures and compositions respond to tensile forces. By evaluating the results of the Split Cylinder Test, engineers can make informed decisions regarding material selection and design strategies to mitigate potential cracking issues in real-world applications.

Furthermore, the Split Cylinder Test is advantageous because it provides insights not only into tensile strength but also into the overall quality and performance of the material. It can be used to compare different formulations of concrete, assess the effects of additives, or evaluate the impact of curing methods on material properties. As a result, this test is a fundamental part of quality control processes in construction and material manufacturing, ensuring that only materials that meet the necessary performance criteria are used in critical applications.

Non-Destructive Testing (NDT) Techniques

These methods preserve the structure's integrity while providing valuable diagnostic data.

1. Ultrasonic Pulse Velocity (UPV): Ultrasonic Pulse Velocity (UPV) is a sophisticated non-destructive testing method that employs high-frequency ultrasonic waves to assess the integrity and quality of concrete structures. By sending these ultrasonic waves through the concrete, UPV is able to effectively detect various internal anomalies such as voids, cracks, and inconsistencies in material uniformity.

The principle behind this technique relies on the fact that the speed at which these waves travel through concrete can provide valuable insights into the material's properties. The application of UPV is particularly prominent in the evaluation of high-strength concrete, which is increasingly used in modern construction due to its enhanced durability and load-bearing capacity.

This method is not only efficient but also offers a reliable means of conducting deep structural analysis without causing any damage to the concrete itself. By measuring the time it takes for the ultrasonic waves to travel through the concrete, engineers and inspectors can determine the material's density and elasticity, which are crucial for assessing its overall structural health. Moreover, UPV is instrumental in identifying potential weaknesses within a concrete structure that may not be visible to the naked eye. For instance, the presence of air pockets or voids can significantly compromise the strength of concrete, leading to potential structural failures if left unchecked. As such, the ability to detect these issues early on allows for timely interventions and repairs, ensuring the longevity and safety of the structure.

In addition to its use in high-strength concrete, UPV can also be applied in various other contexts, such as evaluating the condition of existing structures, monitoring changes over time, and verifying the quality of concrete during the construction phase. The versatility of UPV makes it an invaluable tool in the field of civil engineering and construction management, where maintaining the integrity of concrete structures is of paramount importance.

Overall, the Ultrasonic Pulse Velocity method stands out as a critical technique for professionals in the construction and engineering sectors, providing a non-invasive, efficient, and accurate means of assessing the condition and quality of concrete, thereby facilitating informed decision-making and enhancing structural safety.

2. Rebound Hammer (Schmidt Hammer): The Rebound Hammer, commonly referred to as the Schmidt Hammer, is an essential tool in the field of construction and civil engineering, particularly for assessing the quality of concrete structures. This instrument operates on the principle of measuring the surface hardness of concrete, which serves as a reliable indicator for estimating the compressive strength of the material.

The operation of the Schmidt Hammer involves a spring-loaded mass that is released to strike the concrete surface. Upon impact, the hammer rebounds, and the distance of the rebound is measured. This rebound distance correlates directly with the hardness of the concrete surface; a harder surface will typically result in a greater rebound distance. The results obtained from the Schmidt Hammer can be easily interpreted using a calibrated scale, allowing engineers and inspectors to quickly assess the condition of the concrete without the need for extensive laboratory testing.

One of the primary advantages of using the Rebound Hammer is its efficiency. It is designed for rapid testing, enabling field inspectors to conduct assessments on-site without the need for sample extraction or extensive preparation. This immediacy not only saves time but also reduces costs associated with laboratory analysis, making it a cost-effective solution for routine inspections and quality control processes. Moreover, the Schmidt Hammer is particularly beneficial in various scenarios, such as evaluating existing structures, monitoring the curing process of freshly poured concrete, and conducting non-destructive testing (NDT) to ensure that the concrete meets the required specifications. Its portability and ease of use make it an invaluable tool for engineers and construction professionals who need to gather data quickly and efficiently in diverse environments.

However, while the Rebound Hammer provides valuable insights, it is important to note that its readings can be influenced by several factors, including the surface texture of the concrete, moisture content, and the presence of any surface treatments or coatings. Therefore, it is often recommended to use the Schmidt Hammer in conjunction with other testing methods to obtain a more comprehensive understanding of concrete strength and durability.

In conclusion, the Rebound Hammer (Schmidt Hammer) is a practical and effective instrument for measuring surface hardness, which in turn helps estimate the compressive strength of concrete. Its quick and cost-effective nature makes it a preferred choice for field inspections, providing engineers with essential data to ensure the integrity and safety of concrete structures.

3. Windsor Probe Test: The Windsor Probe Test is a widely recognized method utilized in the field of civil engineering and construction to evaluate the mechanical properties of concrete. This technique involves the use of hardened steel probes, which are specifically designed to penetrate concrete surfaces. The primary objective of the test is to ascertain the penetration depth of these probes, which provides crucial insights into the material's strength and integrity.

The process begins with the careful selection of the test location on the concrete structure. Once the site is determined, the hardened steel probe is driven into the concrete using a specialized apparatus that ensures consistent and controlled application of force. The depth to which the probe penetrates is meticulously measured, as this measurement correlates directly to the localized strength of the concrete in that specific area.

One of the significant advantages of the Windsor Probe Test is its ability to provide localized strength estimates with minimal damage to the concrete structure. Unlike other testing methods that may require extensive sampling or lead to significant alterations in the material, this test is designed to be non-destructive. As a result, it allows engineers and construction professionals to assess the quality and performance of the concrete without compromising the overall integrity of the structure. Furthermore, the data obtained from the Windsor Probe Test can be invaluable for various applications, including quality control during construction, evaluating the condition of existing structures, and informing maintenance and repair decisions.

By analyzing the penetration depth in different areas, engineers can identify potential weaknesses or inconsistencies in the concrete mix or curing process, leading to more informed decisions regarding structural safety and longevity. In conclusion, the Windsor Probe Test stands out as an effective and efficient method for assessing concrete strength. Its non-destructive nature, combined with the ability to provide localized strength estimates, makes it a preferred choice among professionals in the construction and engineering sectors. This test not only aids in ensuring the quality of newly poured concrete but also plays a critical role in the ongoing evaluation of existing structures, thereby contributing to safer and more durable construction practices.

4. Impact-Echo Testing: Impact-echo testing is a non-destructive testing method that utilizes stress waves generated by a short-duration mechanical impact to assess the integrity of concrete structures. This technique is particularly effective in identifying delaminations, voids, and variations in thickness within concrete elements. The fundamental principle behind this method is the generation of stress waves, which travel through the material and reflect back to the surface when encountering any discontinuities or changes in material properties. When a mechanical impact is applied to the concrete surface, it produces stress waves that propagate through the material.

These waves can be classified into two primary types: longitudinal waves and shear waves. As these waves travel, they will encounter various features within the concrete, such as cracks, air voids, or areas of delamination. When the waves hit these anomalies, they are reflected back to the surface, where they can be detected by a sensitive transducer. The time it takes for the waves to return, along with their amplitude and frequency characteristics, provides crucial information regarding the internal condition of the concrete.

This testing method is especially ideal for evaluating bridge decks and slabs, where structural integrity is paramount for safety and performance. Bridge decks, which are subject to various stressors including heavy traffic loads and environmental factors, can develop hidden defects over time. Delaminations, or separations between layers of concrete, can lead to serious structural concerns, while voids may indicate areas where the concrete has not properly cured or has been compromised by erosion or other damage.

Moreover, impact-echo testing is advantageous because it is relatively quick and does not require extensive preparation or the removal of concrete material, making it a cost-effective solution for routine inspections. The results from impact-echo tests can be analyzed to create detailed profiles of the concrete's condition, allowing engineers to make informed decisions about maintenance, repair, or replacement strategies. In summary, impact-echo testing serves as a vital tool in the field of civil engineering, particularly for assessing the structural health of bridge decks and slabs. Its ability to detect internal defects non-destructively makes it an invaluable resource for ensuring the longevity and safety of concrete structures.

5. Ground-Penetrating Radar (GPR): Ground-Penetrating Radar (GPR) is a sophisticated geophysical method that employs electromagnetic waves to investigate and map subsurface features. This technology is particularly adept at identifying various internal structures, such as rebar within concrete, voids or cavities beneath the surface, and areas of moisture accumulation. The operation of GPR involves transmitting short pulses of radar waves into the ground, which then reflect off different materials and structures below the surface. The returning signals are captured and analyzed to create detailed images of the subsurface conditions.

The application of GPR is non-invasive, meaning it does not require any drilling or excavation, making it an ideal choice for large-scale surveys where minimal disruption to the site is desired. This characteristic is especially beneficial in urban environments, where maintaining the integrity of existing structures and minimizing disturbance to the public is crucial. Furthermore, GPR is highly effective for a variety of applications, including but not limited to, locating utilities, assessing the condition of pavements, and conducting archaeological investigations.

In addition to its versatility, GPR is also known for its speed and efficiency. Surveys can be conducted relatively quickly, allowing for the rapid acquisition of data over extensive areas. The data collected can be processed and interpreted in real-time, providing immediate insights that can inform decision-making processes. This capability is invaluable in fields such as construction, where timely information about subsurface conditions can significantly influence project planning and execution.

Moreover, GPR technology continues to evolve, with advancements in radar equipment and data processing techniques enhancing its accuracy and resolution. Modern GPR systems are equipped with high-frequency antennas that can penetrate deeper into the ground while providing clearer images of subsurface features. This improvement allows for more precise mapping of complex geological conditions and better identification of potential issues before they become problematic.

Overall, Ground-Penetrating Radar stands out as a powerful tool in the geophysical toolkit, offering a non-invasive, efficient, and effective means of exploring and understanding the complexities of what lies beneath the surface. Its wide-ranging applications and ongoing advancements make it an essential technology for engineers, archaeologists, and environmental scientists alike.

6. Half-Cell Potential Test: The Half-Cell Potential Test is a critical assessment tool used to evaluate the likelihood of corrosion occurring in steel reinforcement within concrete structures. This test is particularly essential in environments that are prone to moisture, such as marine or humid settings, where the risk of corrosion is significantly elevated due to the presence of chloride ions and other corrosive agents.

The procedure involves measuring the electrical potential of the steel reinforcement relative to a reference electrode, typically a copper-copper sulfate electrode. This measurement provides insights into the electrochemical environment surrounding the steel. The results are expressed in millivolts (mV) and can indicate the likelihood of corrosion activity.

Specifically, more negative values suggest a higher probability of corrosion, while less negative or positive values indicate a lower risk. The importance of conducting the Half-Cell Potential Test cannot be overstated, especially in the context of infrastructure longevity and safety. In marine environments, structures are often exposed to saltwater, which accelerates the corrosion process. Similarly, in humid climates, the presence of moisture can create conditions conducive to corrosion, leading to significant deterioration of the steel reinforcement over time.

Regular monitoring through the Half-Cell Potential Test allows engineers and maintenance teams to identify at-risk areas before significant damage occurs. This proactive approach not only aids in the maintenance planning but also enhances the overall durability and lifespan of the concrete structures. By understanding the corrosion potential, appropriate mitigation strategies can be implemented, such as the use of corrosion inhibitors, cathodic protection systems, or modifications in construction materials.

In summary, the Half-Cell Potential Test serves as an invaluable diagnostic tool in the field of civil engineering, providing essential data that helps in assessing the durability of concrete structures, particularly in challenging environments where corrosion poses a significant threat to structural integrity. Its role in maintaining the safety and longevity of infrastructure cannot be overlooked, making it a fundamental part of corrosion management strategies.

7. Electrical Resistivity: Electrical resistivity is a critical property of concrete that quantifies its resistance to the flow of electrical current. This measurement is not merely a technical specification; it serves as an essential indicator of various physical characteristics of the concrete, such as its moisture content, porosity, and the potential risk of corrosion within the material. When assessing the electrical resistivity of concrete, it is important to understand that the presence of moisture significantly influences this property.

Higher moisture content typically results in lower resistivity values, as water facilitates the movement of ions, allowing electrical current to pass more easily through the concrete matrix. Conversely, drier concrete exhibits higher resistivity, indicating a lower capacity for current flow. This relationship underscores the importance of monitoring moisture levels, especially in environments where concrete structures may be exposed to water or humidity. Porosity is another key factor that affects electrical resistivity.

Concrete with a higher porosity has more voids and air pockets, which can trap moisture and create pathways for electrical current. As such, a porous concrete structure is more susceptible to corrosion, particularly in the presence of aggressive environmental factors such as chlorides from de-icing salts or seawater. By measuring electrical resistivity, engineers can infer the porosity of the concrete and assess its durability and longevity. Moreover, the risk of corrosion is a significant concern in concrete structures, especially those reinforced with steel. When moisture penetrates the concrete and reaches the steel reinforcement, it can lead to corrosion, which compromises the structural integrity of the building. Electrical resistivity measurements provide valuable insights into the likelihood of such corrosion occurring.

Lower resistivity values may indicate a higher risk of corrosion, prompting the need for protective measures or remediation strategies to enhance the concrete's longevity and performance. In practical applications, electrical resistivity testing can be conducted using various methods, including the four-point probe technique and the two-point probe method.

These techniques allow for non-destructive testing of concrete, making it possible to evaluate the material's condition without causing damage. Regular monitoring of electrical resistivity can help in the early detection of issues related to moisture and corrosion, enabling timely interventions that can extend the lifespan of concrete structures. In conclusion, the measurement of electrical resistivity in concrete is a multifaceted assessment that provides vital information regarding the material's moisture content, porosity, and susceptibility to corrosion. Understanding these factors is essential for ensuring the durability and safety of concrete structures, especially in challenging environmental conditions.

8. Acoustic Emission Monitoring; Acoustic Emission Monitoring (AEM) is a sophisticated technique that plays a crucial role in the detection and analysis of sound waves generated by the formation of cracks and other structural defects under mechanical stress. This method relies on the principle that when materials are subjected to stress, they can emit high-frequency sound waves, also known as acoustic emissions, which are indicative of changes occurring within the material's structure. These sound waves can originate from various phenomena, including crack initiation, crack propagation, and the yielding of materials.

The primary advantage of Acoustic Emission Monitoring lies in its ability to provide real-time data regarding the health and integrity of a structure. By continuously monitoring the emissions, engineers and maintenance personnel can gain immediate insights into the condition of critical infrastructure, such as bridges, dams, pipelines, and buildings. This proactive approach allows for the early detection of potential failures, enabling timely maintenance and repairs, which can significantly extend the lifespan of the structure and enhance safety.

In practice, AEM involves the use of sensitive sensors strategically placed on the surface of the structure being monitored. These sensors detect the high-frequency waves generated by the acoustic emissions and convert them into electrical signals for analysis. The data collected can then be processed using advanced algorithms to identify patterns, categorize the types of emissions, and assess the severity of the detected anomalies.

This analysis can help engineers determine whether the structural integrity is compromised and if immediate action is necessary. Furthermore, Acoustic Emission Monitoring is not limited to just the detection of cracks; it can also be employed to monitor various other phenomena, such as corrosion, fatigue, and the overall behavior of materials under different loading conditions.

This versatility makes AEM an invaluable tool in the field of structural health monitoring, as it can be applied across a wide range of materials and structures. In summary, Acoustic Emission Monitoring is a vital technique that enhances the safety and reliability of structures by providing real-time insights into their health through the detection of sound waves produced by crack formation and other stress-related phenomena. Its ability to facilitate early detection of potential issues makes it an essential component of modern engineering practices aimed at maintaining the integrity of critical infrastructure.

9. Laser Scanning & Infrared Thermography Laser scanning is an advanced technology that employs laser beams to capture precise measurements of an object's surface geometry, resulting in highly detailed 3D models. This process involves the use of a laser scanner that emits a laser beam which reflects off surfaces and returns to the scanner. By calculating the time it takes for the laser to return, the scanner can determine the distance to each point on the surface.

The data collected is then processed to create a comprehensive three-dimensional representation of the scanned object or environment. This technique is widely used in various fields, including architecture, engineering, and construction, as it allows for accurate documentation, analysis, and visualization of complex structures. The resulting 3D models can be utilized for a variety of applications such as structural assessments, historical preservation, and even virtual reality simulations.

On the other hand, infrared thermography is a non-destructive testing method that utilizes thermal imaging cameras to detect temperature variations on the surface of materials. This technique is particularly effective in identifying thermal anomalies that may indicate underlying issues such as moisture intrusion, insulation failures, or delamination in composite materials. When moisture is present, it can alter the thermal properties of a surface, leading to noticeable temperature differences that infrared cameras can easily detect. Delamination, which refers to the separation of layers in materials, can also create thermal discrepancies.

By analyzing these temperature variations, technicians can pinpoint areas that require further investigation or remediation, thus preventing potential structural failures and ensuring the longevity of the materials involved. Combining laser scanning with infrared thermography provides a powerful toolset for professionals in various industries. The precise geometric data obtained from laser scanning can be cross-referenced with thermal data from infrared thermography, allowing for a more comprehensive assessment of a structure's condition.

This integrated approach not only enhances the accuracy of inspections but also facilitates more informed decision-making when it comes to maintenance, repairs, and renovations. Overall, the synergy between these two technologies represents a significant advancement in the field of diagnostics and analysis, paving the way for more effective and efficient management of infrastructure and assets.

10. Penetrometer test: The penetrometer test is a widely utilized geotechnical investigation method aimed at determining the physical properties of soil, particularly its strength and consistency. This test is essential in various fields such as civil engineering, construction, and environmental studies, as it provides crucial data for the design and analysis of foundations, retaining structures, and other earthworks.

Types of Penetrometer Tests

There are several types of penetrometer tests, each designed to assess different aspects of soil behavior under stress. The most common types include:

Standard Penetration Test (SPT): This test involves driving a split-barrel sampler into the ground using a hammer dropped from a specific height. The number of blows required to penetrate a certain depth is recorded, which provides an indication of soil density and strength.

Cone Penetration Test (CPT): In this method, a cone-shaped penetrometer is pushed into the ground at a constant rate. The resistance encountered by the cone is measured, allowing for the assessment of soil stratigraphy and engineering properties without the need for soil sampling.

Vane Shear Test: This test is particularly useful for cohesive soils. A vane device is inserted into the soil, and torque is applied until the soil fails. The maximum torque is then used to calculate the undrained shear strength of the soil.

Applications of Penetrometer Tests

Penetrometer tests are invaluable in a variety of applications. They are commonly employed in site investigations for the following purposes:

Foundation Design: Engineers use data from penetrometer tests to determine the load-bearing capacity of soil, which is critical for designing safe and effective foundations for buildings, bridges, and other structures.

Soil Classification: The results help classify soil types based on their physical properties, which is essential for understanding how different soils will behave under various conditions.

Environmental Assessments: Penetrometer tests can be used to evaluate contaminated sites by assessing the soil's properties and its ability to retain or transmit pollutants.

Earthworks and Excavation: Knowledge of soil strength and behavior assists in planning excavation and earthmoving activities, reducing the risk of collapse or instability during construction.

Advantages and Limitations

While penetrometer tests offer many advantages, such as providing immediate results and requiring minimal disturbance to the soil, they also have limitations. The accuracy of the results can be influenced by factors such as soil type, moisture content, and the presence of fractures or voids. Additionally, the interpretation of test results often requires experienced professionals to ensure that the data is correctly analyzed and applied to engineering practices.

Conclusion

In summary, the penetrometer test is a fundamental tool in geotechnical engineering that aids in understanding soil behavior and characteristics. By employing various penetrometer methods, engineers and geologists can gather essential data that informs the design and construction of safe and effective structures. As technology advances, the techniques and equipment used in penetrometer testing continue to evolve, enhancing the accuracy and efficiency of soil investigations.

Emerging Technologies in 2025

AI & Machine Learning Integration in NDT

The integration of Artificial Intelligence (AI) and Machine Learning (ML) into Non-Destructive Testing (NDT) represents a significant advancement in the field of materials inspection and structural integrity assessment. By leveraging sophisticated algorithms and data analytics, AI and ML enhance the interpretation of NDT data, transforming how industries monitor and maintain their assets.

Enhanced Interpretation of NDT Data

One of the primary benefits of incorporating AI and ML into NDT is the enhanced ability to analyze complex datasets generated during inspections. Traditional NDT methods often rely on human expertise to interpret results, which can be subjective and prone to error. AI algorithms, trained on vast amounts of historical NDT data, can identify patterns and anomalies that may not be immediately apparent to human inspectors. This capability not only increases accuracy but also speeds up the decision-making process, allowing for more timely interventions.

For instance, machine learning models can be trained to recognize specific defect types across various materials and conditions. By continuously learning from new data, these models improve over time, resulting in a more robust and reliable interpretation of inspection results. This leads to a deeper understanding of material behavior and failure modes, ultimately contributing to enhanced safety and reliability in critical applications.

Predictive Maintenance Capabilities

Another significant advantage of AI and ML integration in NDT is the enablement of predictive maintenance strategies. Predictive maintenance involves using data-driven insights to anticipate equipment failures before they occur, allowing for maintenance activities to be scheduled proactively rather than reactively. AI algorithms can analyze historical NDT data alongside operational data to predict when and where failures are likely to happen.

By identifying trends and correlations in the data, these systems can provide actionable insights that help organizations optimize their maintenance schedules. This not only reduces downtime and maintenance costs but also extends the lifespan of critical assets. For example, in industries such as aerospace and oil and gas, where equipment reliability is paramount, predictive maintenance powered by AI can lead to significant cost savings and improved operational efficiency.

Real-Time Alerts for Immediate Action

The integration of AI and ML also facilitates the generation of real-time alerts during NDT inspections. As inspections are conducted, AI systems can continuously analyze data streams and flag potential issues as they arise. This capability allows for immediate action to be taken, minimizing the risk of catastrophic failures and enhancing overall safety.

For example, in a manufacturing setting, if an AI system detects an anomaly in the data that suggests a potential defect, it can immediately notify operators or maintenance teams to investigate further. This real-time feedback loop not only enhances the effectiveness of NDT but also supports a culture of safety and proactive management within organizations.

Conclusion: In summary, the integration of AI and Machine Learning into Non-Destructive Testing is revolutionizing the way industries approach asset management and inspection. By enhancing the interpretation of NDT data, enabling predictive maintenance, and providing real-time alerts, these technologies are paving the way for safer, more efficient operations. As AI and ML continue to evolve, their applications in NDT will likely expand, further solidifying their role as essential tools in modern industrial practices.

IoT-Enabled Sensors:

In the realm of modern technology, IoT-enabled sensors play a pivotal role in various applications across multiple industries. These sophisticated sensors are embedded within a variety of systems and devices to continuously monitor critical environmental parameters such as temperature, humidity, and strength gain.

This continuous monitoring is essential for ensuring optimal performance and safety in settings ranging from industrial manufacturing to agricultural practices.

Temperature Monitoring Temperature sensors are vital components in many applications, particularly in processes where thermal regulation is crucial. For instance, in manufacturing facilities, maintaining a specific temperature range can significantly affect product quality and operational efficiency. IoT-enabled temperature sensors can provide real-time data, allowing for immediate adjustments to heating or cooling systems, thereby preventing potential spoilage or damage to sensitive materials.

Humidity Tracking Similarly, humidity sensors are integral in environments where moisture levels must be controlled. In sectors like food storage and pharmaceuticals, maintaining appropriate humidity levels is essential to prevent spoilage and ensure product integrity. By utilizing IoT-enabled humidity sensors, businesses can gain insights into environmental conditions and respond proactively to any fluctuations, thus safeguarding their products.

Strength Gain Measurement Strength gain sensors are particularly important in construction and civil engineering. These sensors monitor the curing process of concrete and other materials, providing critical data on strength development over time. This information is essential for determining when structures can safely bear loads, thereby ensuring safety and compliance with building regulations. The integration of IoT technology allows for the continuous collection and analysis of strength gain data, enabling engineers to make informed decisions based on real-time information.

Wireless Data Transmission One of the standout features of IoT-enabled sensors is their ability to transmit data wirelessly. This capability eliminates the need for cumbersome wiring and allows for the placement of sensors in hard-to-reach or remote locations. The data collected by these sensors is transmitted through secure wireless networks, making it accessible for remote analysis. This means that stakeholders can monitor conditions from anywhere in the world, using smartphones, tablets, or computers.

Remote Analysis and Decision Making The data gathered by IoT-enabled sensors is not just for monitoring purposes; it is also analyzed to extract valuable insights. Advanced analytics tools can process this data to identify trends, predict potential issues, and optimize operational processes. For example, predictive maintenance can be implemented based on sensor data, allowing companies to address problems before they escalate into costly failures.

This proactive approach can lead to significant cost savings and improved efficiency. In conclusion, IoT-enabled sensors represent a significant advancement in the monitoring and management of environmental conditions. By embedding these sensors to track temperature, humidity, and strength gain, industries can ensure better quality control, enhance safety measures, and optimize their operations through the power of wireless data transmission and remote analysis. The ongoing evolution of IoT technology promises even greater capabilities in the future, further transforming how we interact with and manage our environments.

Microwave NDT:

Microwave Non-Destructive Testing (NDT) is a sophisticated technique that employs microwave signals to assess the integrity and condition of materials and structures without causing any damage. This method is particularly advantageous when it comes to identifying moisture content, voids, and chemical changes within various materials, making it a valuable tool in numerous industries.

Applications of Microwave NDT

One of the primary applications of microwave NDT is in the detection of moisture. Moisture content can significantly affect the physical properties of materials, such as their strength and durability. For instance, in construction, the presence of moisture within concrete can lead to structural weaknesses over time. Microwave NDT allows for the rapid and non-invasive assessment of moisture levels, enabling timely interventions before significant damage occurs.

Additionally, this technique is effective in identifying voids within composite materials. Voids can compromise the structural integrity of components, especially in aerospace and automotive applications where material reliability is critical. By utilizing microwave signals, technicians can detect these voids without having to cut or dismantle the components, thus preserving their integrity and functionality.

Detecting Chemical Changes

Microwave NDT is also promising for detecting chemical changes within materials. As materials undergo degradation or chemical reactions, their dielectric properties can change. This method allows for the monitoring of these changes in real-time, providing insights into the health of the material. This is particularly useful in industries such as oil and gas, where the integrity of pipelines and storage tanks is paramount.

Accessibility Challenges

One of the significant advantages of microwave NDT is its ability to assess inaccessible components. Many industrial applications involve structures that are difficult to reach or inspect using traditional methods. For example, in the case of aircraft or large machinery, certain components may be hidden from view or difficult to access. Microwave NDT can penetrate various materials, allowing for effective inspection of these hard-to-reach areas without the need for extensive disassembly.

Conclusion

In summary, microwave NDT represents a revolutionary approach to non-destructive testing. Its ability to detect moisture, voids, and chemical changes makes it an invaluable asset across multiple industries. By facilitating inspections of inaccessible components, this technique not only enhances safety and reliability but also contributes to the longevity of critical structures and materials. As technology advances, the applications and effectiveness of microwave NDT are likely to expand, further solidifying its role in modern engineering and maintenance practices.

🌍 Global Applications

North America: In North America, there is a significant emphasis on integrating artificial intelligence (AI) into non-destructive testing (NDT) methodologies. This approach not only enhances the accuracy and efficiency of inspections but also promotes sustainability in various industries. Companies are increasingly leveraging AI algorithms to analyze data collected during NDT processes, allowing for real-time decision-making and predictive maintenance. Furthermore, the focus on sustainability is driving innovation in NDT practices, as organizations seek to minimize waste and reduce their environmental footprint. This includes the adoption of eco-friendly materials and methods that align with regulatory standards aimed at protecting the environment while ensuring safety and compliance in sectors such as construction, manufacturing, and aerospace.

Europe: In Europe, the standardization of NDT protocols is a critical focus area. The continent is home to various regulatory bodies and industry associations that work diligently to establish uniform guidelines and best practices for NDT procedures. This standardization is essential for ensuring consistency and reliability across different sectors, including oil and gas, automotive, and civil engineering. Additionally, there is a robust emphasis on training and certification programs to equip professionals with the necessary skills and knowledge to perform NDT effectively. By fostering a culture of continuous learning and improvement, European countries aim to enhance the overall quality of inspections and ensure that technicians are well-versed in the latest technologies and methodologies, thus promoting safety and operational excellence.

Asia: The rapid adoption of Ground Penetrating Radar (GPR) and Ultrasonic Pulse Velocity (UPV) technologies in Asia is largely driven by the region's extensive infrastructure expansion initiatives. Countries such as China and India are investing heavily in the development of transportation networks, urban development, and public utilities, necessitating advanced NDT solutions to assess the integrity of new constructions and existing structures. GPR is particularly valuable for subsurface investigations, allowing engineers to detect voids, utilities, and other anomalies without invasive methods. Meanwhile, UPV is employed to evaluate the quality of concrete and masonry, ensuring that materials meet required standards. The swift integration of these technologies not only enhances construction safety but also optimizes resource allocation and project timelines, ultimately contributing to the region's economic growth.

Africa & Middle East: In the diverse regions of Africa and the Middle East, the use of portable NDT tools has become increasingly prevalent, particularly for remote site evaluations. These portable devices enable inspectors to conduct thorough assessments in locations where traditional laboratory facilities may be lacking or inaccessible. This capability is especially crucial in areas undergoing rapid development or facing logistical challenges. The flexibility and ease of use of portable NDT tools allow for quick inspections of pipelines, bridges, and other critical infrastructure, ensuring that potential issues are identified and addressed promptly. Moreover, the adoption of these technologies is helping to build local expertise and capacity, as training programs are being developed to empower local technicians with the skills necessary to perform NDT in their communities, thereby fostering economic development and enhancing safety standards across the region.

Looking Ahead: Embracing Sustainable Concrete Solutions

As we move toward 2026, the construction industry is witnessing a significant transformation driven by innovations in concrete mix designs that are paving the way for a more sustainable future. These advancements are not merely incremental improvements; they represent a paradigm shift in how concrete is produced, utilized, and perceived within the realm of construction. With a heightened focus on sustainability and performance, the emergence of carbon-free concrete, the development of progressive mixers, and the implementation of enhanced testing systems are set to revolutionize the industry.

Carbon-free concrete is at the forefront of these innovations, aiming to drastically reduce the carbon footprint traditionally associated with concrete production. This new breed of concrete incorporates alternative materials such as recycled aggregates, industrial by-products, and innovative binding agents that minimize or eliminate the need for Portland cement, one of the primary contributors to greenhouse gas emissions. By leveraging these materials, the construction sector can significantly lower its environmental impact while maintaining the structural integrity and durability that concrete is known for.

In addition to carbon-free solutions, the evolution of progressive mixers is enhancing the efficiency and effectiveness of concrete production. These advanced mixers are designed to optimize the mixing process, ensuring a more uniform distribution of materials and improving the overall quality of the concrete. By utilizing cutting-edge technology, such as automated controls and real-time monitoring, these mixers can adapt to varying material characteristics and environmental conditions, leading to better performance and reduced waste. This not only contributes to sustainability but also helps in achieving cost-effective solutions for construction projects.

Furthermore, enhanced testing systems are crucial in validating the performance of these innovative concrete mixes. With the introduction of more sophisticated testing methodologies and equipment, engineers can better assess the properties of concrete, such as its strength, durability, and resistance to environmental factors. This ensures that the new sustainable concrete solutions meet or exceed industry standards, providing confidence to construction professionals and stakeholders alike. As these testing systems become more integrated into the production process, they will play a vital role in fostering trust and reliability in the use of sustainable concrete.

As the construction industry evolves, it is imperative for engineers and construction professionals to stay informed about these transformative changes. Continuous education and engagement with the latest research and developments in sustainable concrete technologies will empower them to make informed decisions that align with environmental goals. By embracing these innovations, professionals can not only contribute to a more sustainable construction landscape but also enhance the quality and performance of their projects. The future of construction lies in the commitment to sustainability, and by adopting these advanced concrete solutions, the industry can build a better tomorrow for generations to come.

We are Amazon Associates and earn advertising fees

By : Siv Brasha

Comments